The World’s Tallest Climbing Wall

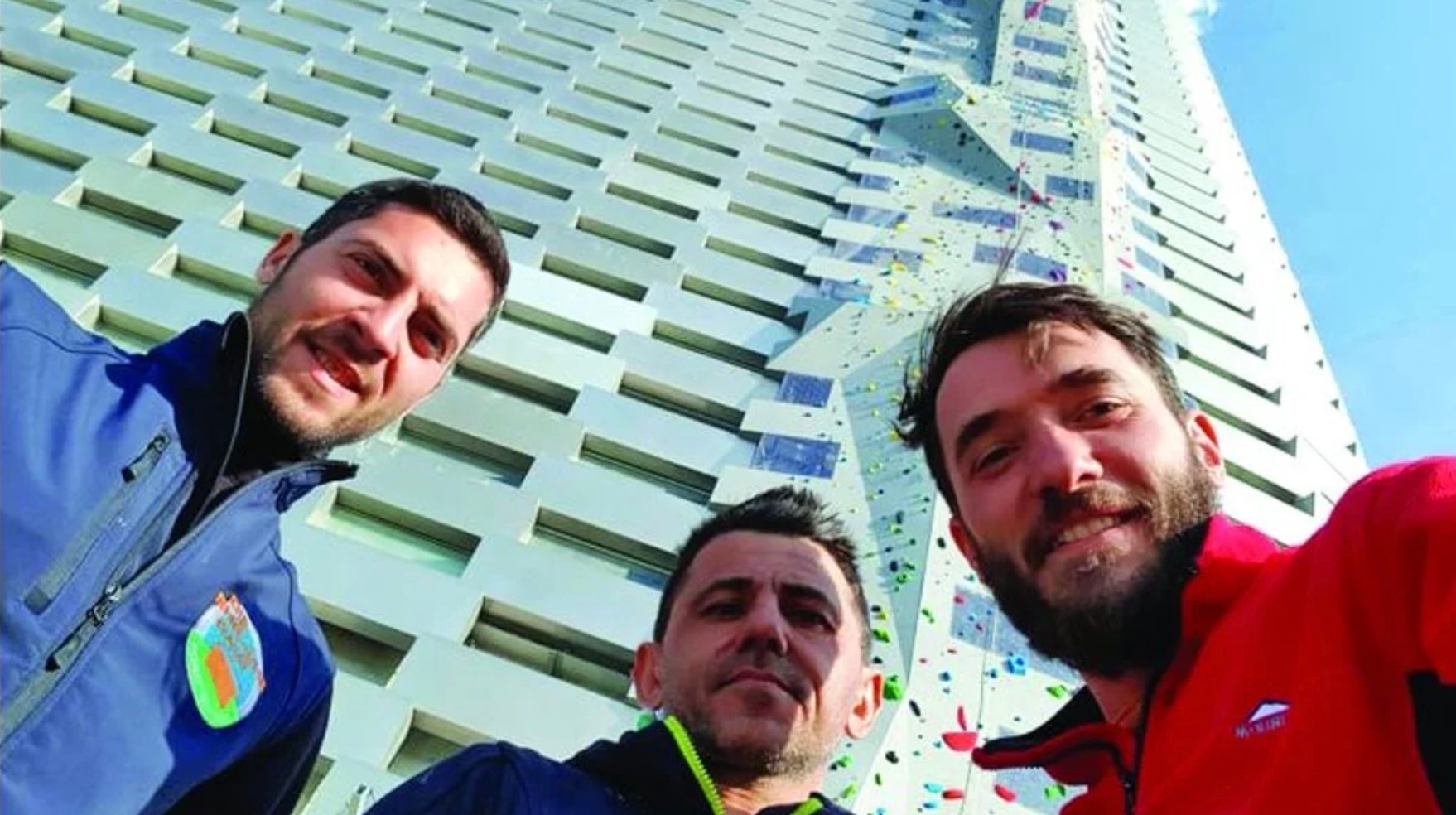

The route setters after setting five routes, each 262 feet tall. From left to right: Valentin Borisov, Milen Vidinovski and Plamen Kostadinov.

Nope, it’s not in a gym. It’s on the outside of the world’s cleanest waste-to-energy power plant.

Fifty-five tons of steel, 24 tons of fiberglass and plexiglass and eight Walltopia technicians: with that and more, the tallest climbing wall in the world was constructed on the exterior of CopenHill, a part of the cleanest waste-to-energy power plant in the world. The facility is called Amager Bakke, and it resides in Copenhagen, Denmark.

The wall is 262 feet tall and 30 feet wide—enough space for five routes at four pitches each. The routes get progressively more difficult with each pitch.

And, when you top out, you can ski down. A (dry) ski slope starts at the roof and winds down around the building. The plant, envisioned and designed by Bjarke Ingels, converts waste into heat and power. Unlike other refuse sites, CopenHill’s utility creates enjoyment. Visitors of the “human-made mountain,” as Ingels put it in a WIRED interview, can hike, ski and now climb.

Walltopia designed, constructed and route-set the wall. The panels had to be cut at an exact height to match the brick-like pattern of the building’s exterior. Transparent panels that correspond to the building’s windows alternate with ones that blend with the shiny silver “blocks” of the building. The result is a functional wall that integrates with the architecture.

“We had to color match as close as possible the climbing wall with the metal facade,” Vasil Sharlanov told Gym Climber. Sharlanov is current head of sales at Walltopia, and was the head of design and architecture at the time of construction.

“This was actually quite difficult since the nature of the facade is shiny, and the walls have friction for climbing and are less shiny, but still had to be close enough visually,” Sharlanov said.

Walltopia used plexiglass for the transparent sections. “Screws cannot be used with plexiglass, so all connections needed to be made with bolts and fasteners,” said Ivan Natov, Walltopia’s project manager. “This is a very precise job, and you barely have any margin for error.”

By alternating fiberglass with plexiglass, Walltopia struck a balance between providing the most desirable climbing conditions and adequate light into the offices behind the wall.

Although construction was finished in November 2019, the process took longer than expected due to heavy winds. “There were days that the platform was shaking so much that it was not possible to lift it safely to the installation position,” Sharlanov said.The construction process itself was also unusual. While construction is commonly done from the ground up, this time Walltopia installed the panels into the steel structure from top to bottom and gradually removed the lift platform. The panels were pre-assembled on the ground to make sure there were no discrepancies and then mounted with the platform.

Because winter in Denmark is too cold for climbing, route-setting was postponed until this past spring. CopenHill requires visitors to carry a multi-pitch certification to climb to the top, and those under 18 must be accompanied by a climber who is at least 21 years old. The wall is, in more ways than one, a big addition to a country not known for its climbing access.